Trusted Manufacturer Partner

Our aim is to ensure quality that each product is flawlessly crafted, meeting the highest standards of precision and durability. We priorities open communication, forging strong partnerships with our clients, understanding their needs, and delivering on promises.

Yes, we understand that you may want to check the quality of stitching or sublimation & feel the quality of the fabric. It generally takes us one week to manufacture an article and three to four days to get it delivered to you.

Our Standard turnaround time is two weeks for 100 to 1000 pieces, excluding shipping time. We may need three weeks for some articles, like American football uniforms, baseball uniforms, and ice hockey uniforms.

The minimum Order Quantity is 100 per article or set.

We can ship anywhere worldwide, including the USA, Canada, UK, Europe & Australia.

Our preferred payment method is a wire transfer to our bank account. However, we accept payments through Western Union, MoneyGram, Xoom, and other hassle-free payment services.

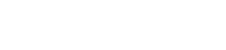

OUR COLLECTIONS

Featured Products

Clothing

Vision Apparel

Clothing Vision Apparel and just changed the face of boxing gear forever and we continue to struggle towards our goal. We have built an extremely good reputation in the market. Also Clothing Vision Apparel provides a complete range of Street, Fitness & Sports gears & wears.

Made in

Pakistan.

Durable

Quality.

Easy

Customization.

Quality

Warranty.

PRODUCTION PROCESS

Pattern Making

Patterns are designed according to the required sizes and designs. Each product has a different pattern, designed with accuracy and precision.

Pre-Production Sample

Before bulk production, we get your approval by making a sample and shipping it to you. Once approved, we move to the next step.

Material & Fabric Sourcing

Fabric is sourced from the most reliable and trusted fabric suppliers. The fabric is stored in the fabric store in racks, and fabric inspection is done before shifting it to the cutting department.

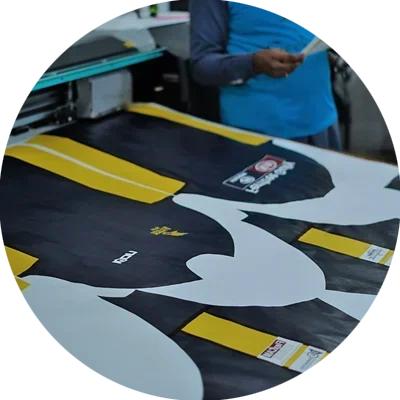

Cutting & Printing Process

After sourcing, the fabric is cut down into pieces according to the patterns. After that, according to our client's requirements, these pieces have printing or embroidery.

Sewing & Quality Check

Cut panels are sewn together, and the design finally comes to life. After that, all items are carefully inspected to ensure the highest quality standards, which helps us to remain one of the best sportswear and activewear manufacturers.

Packing & Delivery

After that, all items get pressed, tags are installed, and packed in poly bags. Finally, all items get packed in cartons and shipped using reliable delivery services.

WHY CHOOSE CLOTHING VISION?

NO MINIMUM

Unlike others we don’t charge an arm & a leg for a single item order, so you can get a customized product at the same price you’d pay for a comparable branded product.

COMPLETE CONTROL

You control the price as we give you a progressive discount based on your order. With dozens of style options & a massive size chart, experience unparalleled control over your order.

SMART PRODUCTION

To live up to our commitment of world class quality, we have in-house design, manufacturing & printing facilities, so that no integral process is outsourced to a 3rd party.

CLOTHING VISION TEAM

With decades of experience behind us & with the singular goal of making mass customization truly mainstream… in us you will find a helpful partner every step of the way.

Interesting Facts

CUTTING PROCESS

The fabric is laid out, marked with the T-shirt pattern, and then cut along the lines. The cut pieces are then sorted and prepared for sewing.

SCREEN PRINTING

Screen printing is very much an art in more ways than one. printers or promotional clothing printers take the same care over the quality printing as we.

EMBROIDERY

Embroidery is a customization process which consists of applying decorative designs onto fabric using a needle.

STITCHING

We have high quality machinery to produce customized clothing. Quality control measures to ensure high-quality apparels

OUR CERTIFICATES